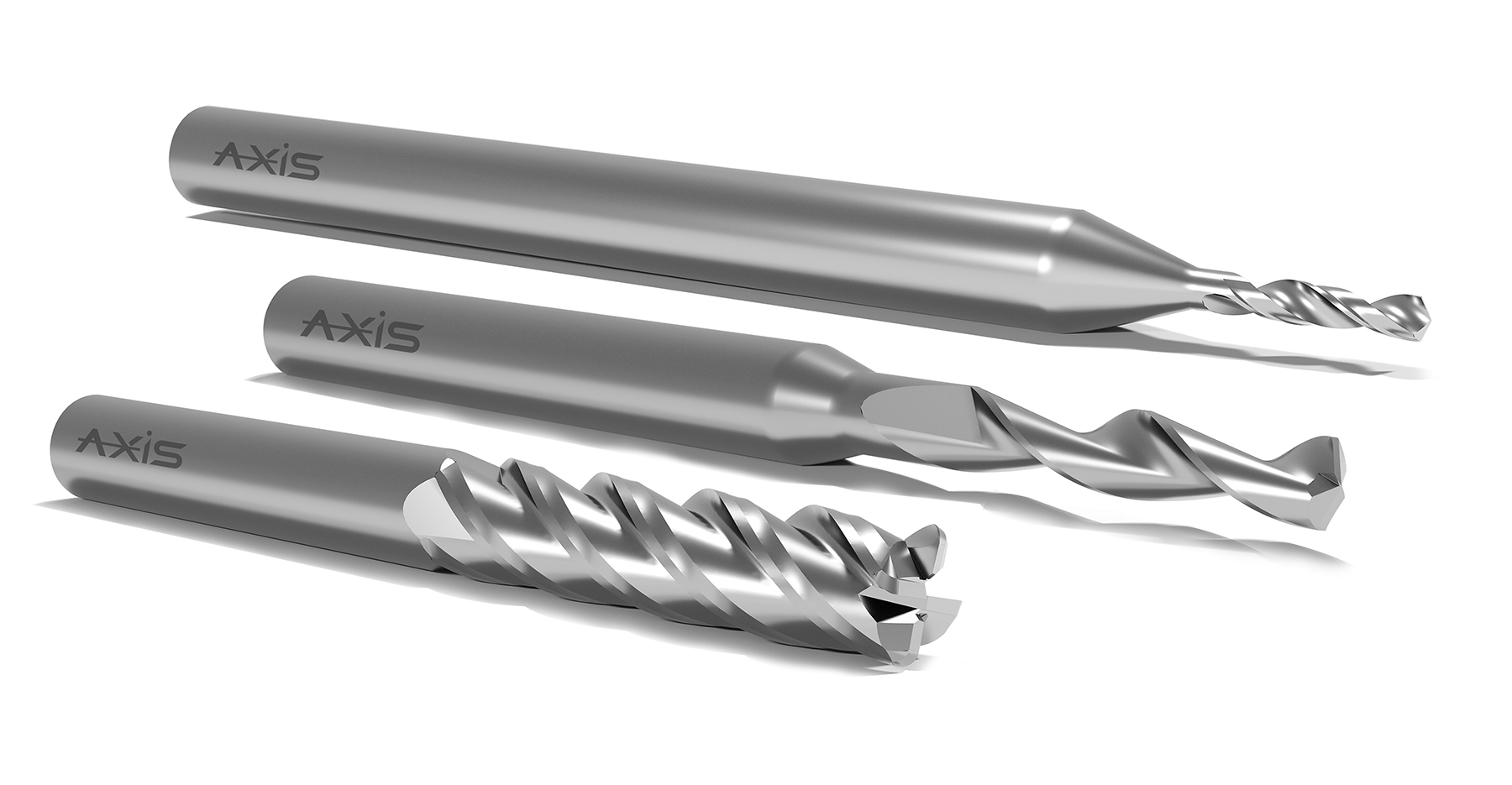

Monaghan Tooling Group introduces Axis high precision micro tools for digital dentistry, including machining of dental appliances and fixtures. With unique geometries and NextGen coatings, these tools enable detailed and accurate machining for unparalleled precision and finish quality. Axis micro tools are available for the broad range of dental machining challenges – from soft waxes to challenging Zirconia. Superfinishing maintains the cutting geometry of tools which reduces flute friction to drastically improve chip evacuation while machining soft materials like PMMA, PEEK, and wax. Smoother cutting reduces the heat generated. Controlled and repeatable edge honing ensures consistent, repeatable results. This superfinishing enhances adhesion of PVD, producing an extremely low coefficient of friction when machining hard and difficult to machine materials like chrome cobalt and titanium. Shank sizes of 3.00, 4.00, and 6.00mm, are available, with diameters from 0.30 to 3.00 mm, coupled with unique geometries and finishes and coatings, making Axis micro tools ideal for virtually all digital dentistry machining applications.

Axis micro tools are available through Monaghan Tooling Group with industry-leading lead times. For more information visit https://monaghantooling.com/micro-machining-tooling/.