“The Stratasys DentaJet XL solution is engineered specifically for digital dental labs that must deliver high volumes of applications without sacrificing quality, helping them overcome significant challenges in finding and retaining qualified technicians as they work to meet growing market demand,” said Ronen Lebi, Vice President, Stratasys Dental. “It is the most efficient production solution we have developed to date, geared to produce highly accurate crown and bridge, implant, and aligner models and surgical guides simultaneously at scale.”

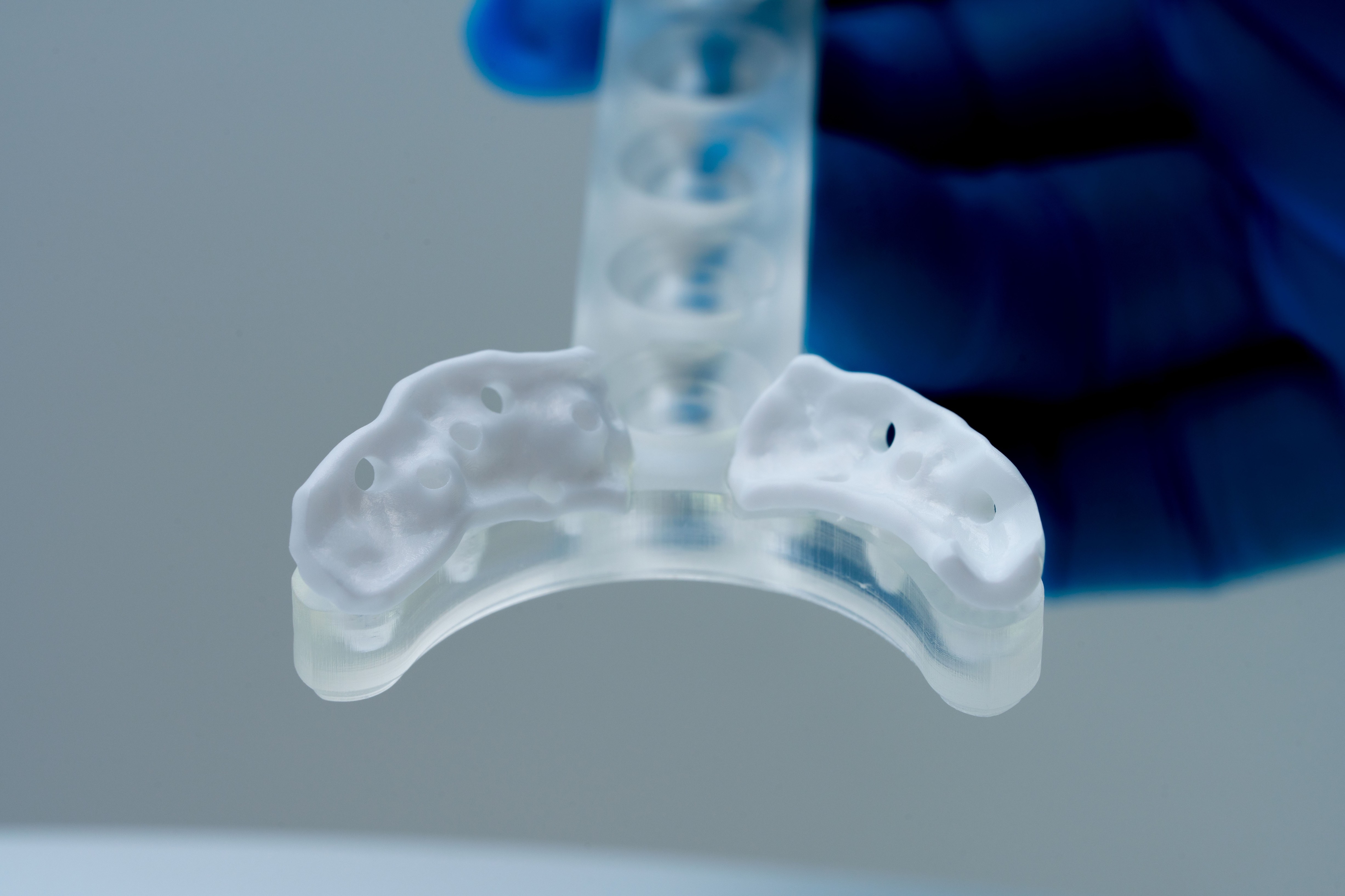

The new PolyJet™ multi-material 3D printer is designed to run in a production setting with minimal human intervention. With advanced software print prep and print management features, as well as unattended printing and curing, labs can reduce up to 90 percent of their labor costs. The introduction of new printing modes and larger cartridges results in up to 67% lower cost per part. This new printer can be integrated with new validated, fast and large batch post processing workflows for support removal. It also allows for printing two materials simultaneously. And it can improve lab productivity and lowers costs making it the “go-to” solution for large volume production labs around the world.

“Incorporating the DentaJet XL 3D printer into our laboratory has significantly improved our digital workflow,” said James Dobson, Vice President, Digital Production, Dobson Ortho Laboratories and one of the first to implement the solution. “With its large print tray, 4X larger resin cartridges, and hot-swap capabilities, we have already achieved significant material and labor savings. Creating print jobs has become extremely fast and simple with the automatic part nesting features. Furthermore, its sealed resin system ensures a healthier workplace for our team.”

“The new Super High-Speed Mode allowed us to significantly increase our production of clear aligners by nearly 50%, without adding any additional labor and at a much-reduced cost per part,” said Prof. Armando Razionale, Airnivol, and one of the first customers implementing the solution in Europe. “Plus, by integrating the DentaJet XL with the automatic support removal workflow, we are saving a tremendous amount of time and labor in the final stage of production. It’s almost like we added a virtual lab technician!”

The first DentaJet XL customers were able to achieve notable production results:

• Up to 16 implant cases (surgical guide and model) in 6 hours 30 minutes

• Up to 102 crown & bridge models in 4 hours 31 minutes

• Up to 28 orthodontic models in 6 hours 37 minutes

• Up to 36 aligner arches in 2 hours 14 minutes

Notable features of this new solution include:

• Uninterrupted printing, even for the largest jobs with 4kg resin cartridges and hot-swap.

• Significantly reduced print prep times and integrated fleet management with intuitive GrabCAD Print software.

• Increased production speed of clear aligner arches by up to 30 percent with a super high-speed mode.

• Dual-material printing, which allows labs to increase output by printing two materials at once.

• Efficient post-processing with integrated third-party workflows for large batch support removal. This streamlines processes and saves time and labor.

About Stratasys

Stratasys is leading the global shift to additive manufacturing with innovative 3D printing solutions for industries such as aerospace, automotive, consumer products and healthcare. Through smart and connected 3D printers, polymer materials, a software ecosystem, and parts on demand, Stratasys solutions deliver competitive advantages at every stage in the product value chain. The world’s leading organizations turn to Stratasys to transform product design, bring agility to manufacturing and supply chains, and improve patient care.

To learn more about Stratasys, visit www.stratasys.com.

Pictured: The new Stratasys DentaJet XL Printer for high-volume dental labs, cutting labor costs and time needed for printing. (Photo: Business Wire)

In the fast-paced world of digital dentistry, precision and aesthetics are paramount. Dental professionals constantly seek ways to enhance their 3D printing outcomes, balancing the need for durability with the demand for natural-looking results. Enter Ackuretta’s latest innovation: the NFinity nitrogen generator, a game-changer set to transform the landscape of dental 3D printing post-curing.

In the fast-paced world of digital dentistry, precision and aesthetics are paramount. Dental professionals constantly seek ways to enhance their 3D printing outcomes, balancing the need for durability with the demand for natural-looking results. Enter Ackuretta’s latest innovation: the NFinity nitrogen generator, a game-changer set to transform the landscape of dental 3D printing post-curing.

Productive Dentist Academy (PDA), the nation’s leading dental practice management, coaching, and marketing firm, is excited to announce the launch of the Clinical Calibration Institute, a groundbreaking educational program that bridges the gap between academic clinical knowledge and real-world patient care for associate dentists and doctor owners. The inaugural Clinical Calibration Institute will be kicked off at the 20th Anniversary PDA Conference this September 12-14, 2024, at the Hyatt Regency, in Frisco, Texas, and run concurrently with the PDA Conference. Thereafter, the program will run in four-month courses.

Productive Dentist Academy (PDA), the nation’s leading dental practice management, coaching, and marketing firm, is excited to announce the launch of the Clinical Calibration Institute, a groundbreaking educational program that bridges the gap between academic clinical knowledge and real-world patient care for associate dentists and doctor owners. The inaugural Clinical Calibration Institute will be kicked off at the 20th Anniversary PDA Conference this September 12-14, 2024, at the Hyatt Regency, in Frisco, Texas, and run concurrently with the PDA Conference. Thereafter, the program will run in four-month courses.

Midmark Corp., a leading dental solutions provider focused on the design of the clinical environment to improve the delivery of care, today announced the launch of its next generation Midmark M9 and M11 Steam Sterilizers. The sterilizers have been designed for enhanced durability and ease of use, with integrated features to help care teams gain instrument processing and documentation compliance efficiencies.

Midmark Corp., a leading dental solutions provider focused on the design of the clinical environment to improve the delivery of care, today announced the launch of its next generation Midmark M9 and M11 Steam Sterilizers. The sterilizers have been designed for enhanced durability and ease of use, with integrated features to help care teams gain instrument processing and documentation compliance efficiencies.

MouthWatch, LLC, a leader in developing digital technology solutions that drive success for dental professionals, improve oral health care, and enhance the overall patient experience, has opened nominations for its 7th annual Teledentistry Innovation Awards. These unique awards, known as “The Tellies,” recognize a broad spectrum of individuals, programs, and organizations, utilizing teledentistry and virtual dental care applications to expand access to care, improve oral health and ultimately enhance overall health and well-being.

MouthWatch, LLC, a leader in developing digital technology solutions that drive success for dental professionals, improve oral health care, and enhance the overall patient experience, has opened nominations for its 7th annual Teledentistry Innovation Awards. These unique awards, known as “The Tellies,” recognize a broad spectrum of individuals, programs, and organizations, utilizing teledentistry and virtual dental care applications to expand access to care, improve oral health and ultimately enhance overall health and well-being.