- At the upcoming LMT Lab Day in Chicago, Lithoz will highlight a wide array of their fascinating 3D-printed lithium disilicate veneers and crowns, jointly developed with Ivoclar, in their latest development stage

- This material, based on IPS e.max lithium disilicate powder from Ivoclar, will open up a long-awaited path to the series production of patient-specific, natural-looking dental restorations

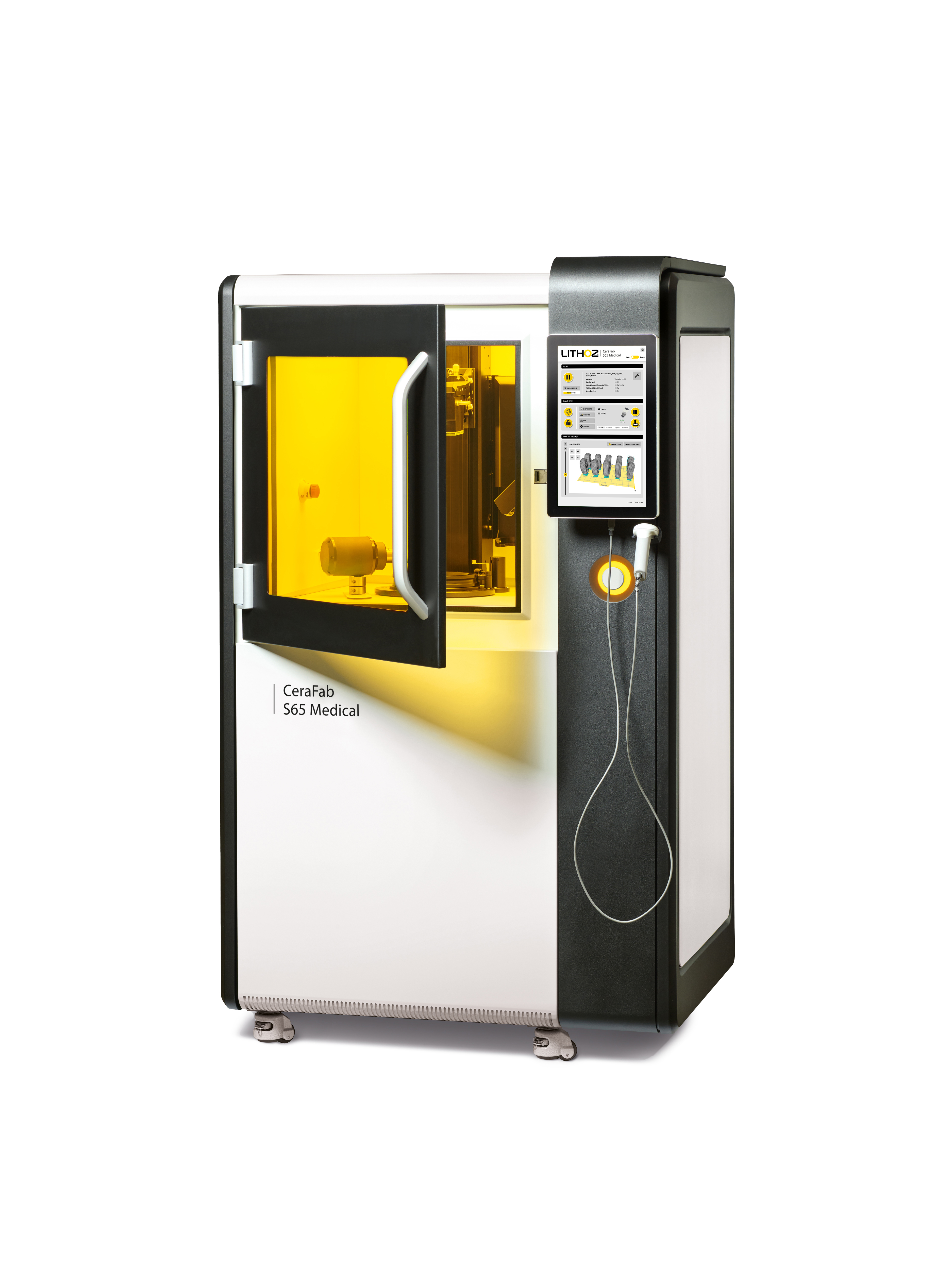

- Lithoz will present a full illustration of the entire LCM printing process, alongside a range of restorations available for ‘touch and feel’

At the upcoming LMT Lab Day in Chicago, Lithoz GmbH, world market and technology leader in high-performance ceramic materials and 3D printers, will present the next development stage of their lithium disilicate material for dental 3D printing. This material has been jointly developed with Ivoclar, one of the world’s leading manufacturers of integrated solutions for aesthetic, high-quality dental applications.

The 3D-printable lithium disilicate is based on IPS e.max lithium disilicate powder from Ivoclar and opens up a long-awaited path to the patient-individual serial production of high-profile all-ceramic dental restorations. With veneers as thin as 0.3 mm and crowns with high levels of detail especially at the occlusal surfaces reaching sharp and natural representation of the features combined with natural translucency, lithium disilicate dental restorations can finally be fabricated in scalable yet individual series production. In one single print run, a multitude of patient-specific restorations can be created with exceptional aesthetics comparable to those of traditional manufacturing. This will launch a new era of unprecedented production efficiency for large dental labs.

Further innovative dental applications made possible by the impressive precision of LCM technology will be on display at the Lithoz booth, including fully patient-specific osseoconductive and bioresorbable mandibular augmentations (hydroxy apatite or tricalcium phosphate) and additively serially manufactured dental implants made of zirconia (TZP-A) or alumina-toughened zirconia (ATZ). At the Lithoz booth, visitors can pick up a range of these parts for a thorough ‘touch and feel’ examination, guided by Lithoz dental experts from Austria and the USA, while also learning about every step of the manufacturing workflow via an exhibition of the whole process.

Dr. Daniel Bomze, Director of Medical Solutions at Lithoz GmbH, will host a free interactive workshop presenting ‘3D-Printed Lithium Disilicate Restorations: The Efficient Way to Perfect Dental Aesthetics’. This talk, showcasing the new production process for these innovative parts, will take place on February 23rd at 10:45am.

Lithoz at LMT Lab Day Chicago:

➢ Booth F-24 in the East Exhibit Hall