TrueDent™ Resin is Stratasys’ First FDA-Cleared Medical Device New TrueDent™ Resin Enables 3D Printing of High-Fidelity Polychromatic Dental Appliances

Stratasys Ltd. (NASDAQ: SSYS), a leader in polymer 3D printing, today introduced TrueDent™ the first monolithic, full-color 3D printed permanent dentures solution. The TrueDent resin enables labs to create permanent, natural looking gums with accurate tooth structure, shade, and translucency in one continuous print.

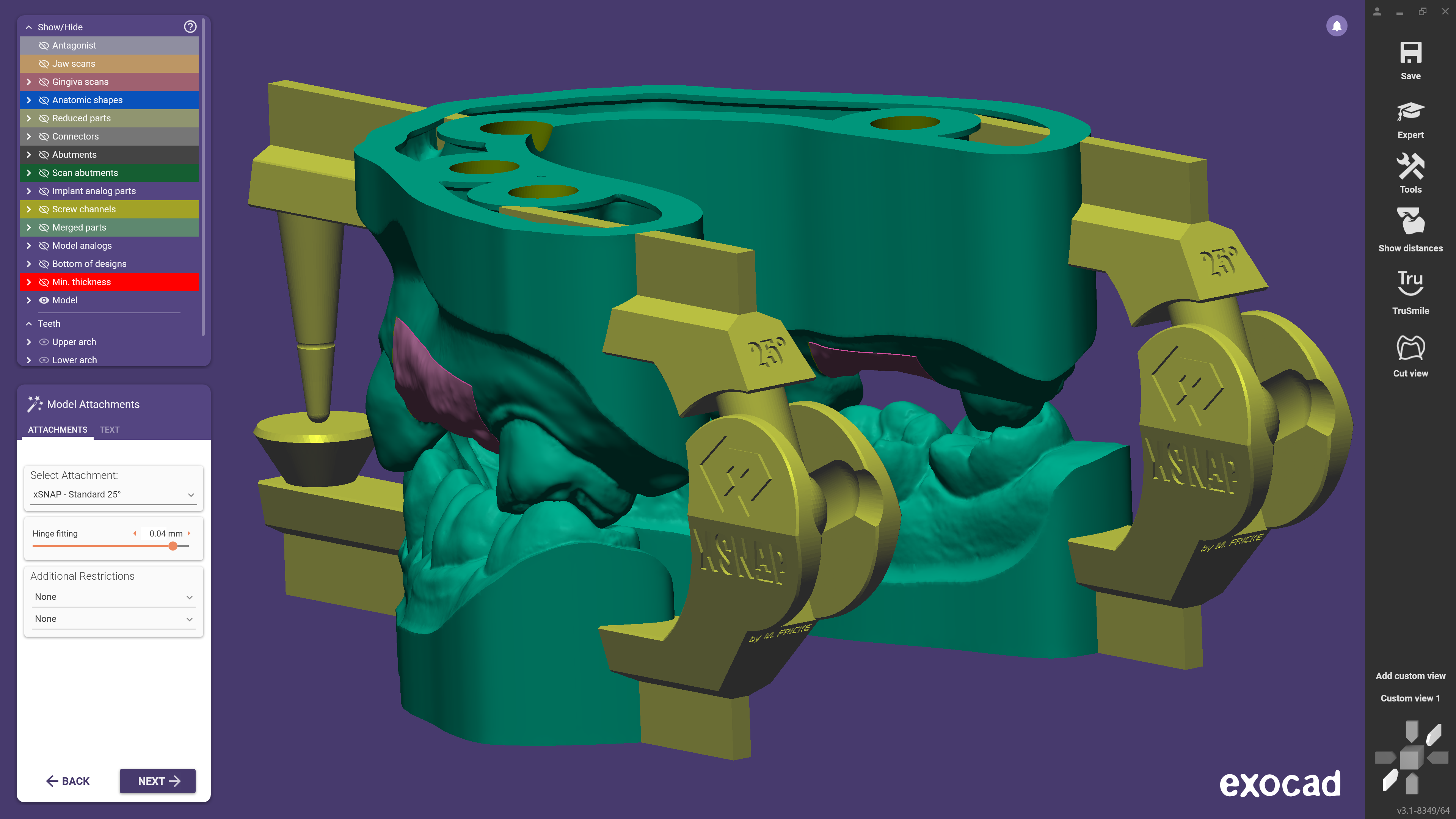

TrueDent is an FDA-cleared (Class II) dental resin made specifically for the fabrication of dental appliances, including removable dentures. The resin was developed to be printed exclusively with the Stratasys® J5 DentaJet® 3D printer and GrabCAD® Print software platform. The complete solution will allow dental labs to scale manufacturing by simplifying workflow and reducing processing time for dentures, while achieving a personalized, highly aesthetic dental appliance.

TrueDent is designed to eliminate several barriers for patients and laboratories:

● Potential to reduce chair time for office visits, measurements, fittings and adjustments.

● High fidelity match between scan, design and fit.

● Scalable digital solutions are repeatable, and can provide consistent production of accurate, well-fitting dentures.

● Can increase efficiency through streamlined workflow with less time between scan and delivery.

“Until now, printed dentures and appliances had to be designed and manufactured in multiple parts and bonded together,” said Frank Acosta, Owner of AA Dental Design. “The TrueDent solution, utilizing Stratasys’ systems and software takes a lot of that stress out. It simplifies the process, lowers the costs, and allows for dentures and temporaries to be produced much faster, achieving incredible aesthetics. We can now expand our prosthetic service printing multi-colored personalized appliance at scale.”

The global dentures market, estimated by Stratasys at $5.5 billion, is challenged to meet the rising global demand for dentures and appliances through conventional methods due to a shortage of skilled dental laboratory technicians. According to research from iData, in 2021, more than 4.2 million full dentures were created in the United States, and 18 million full dentures were sold worldwide. Of that total, only five percent are estimated to be created through a 3D printed solution. The TrueDent solution offers a scalable alternative with a digital workflow that delivers a predictable, high-quality, fully finished result.

“This new solution will be transformative for the dental industry, and we believe it will help our customers significantly reduce the time and cost of producing dentures and temporaries,” said Ronen Lebi, Vice President of Dental at Stratasys. “Stratasys continues to push the boundaries of digital dentistry leveraging our portfolio of advanced 3D printing technologies, including hardware, resins and software to deliver disruptive solutions that make a difference.”

TrueDent resin is patent pending and currently available only in the U.S., and only compatible with the Stratasys J5 DentaJet printer. The material will be unveiled at LMT Lab Day Chicago, February 23-25, 2023. Click the following links to learn more about the TrueDent resin and TrueDent application and Stratasys’ other dental solutions.

Stratasys is leading the global shift to additive manufacturing with innovative 3D printing solutions for industries such as aerospace, automotive, consumer products and healthcare. Through smart and connected 3D printers, polymer materials, a software ecosystem, and parts on demand, Stratasys solutions deliver competitive advantages at every stage in the product value chain. The world’s leading organizations turn to Stratasys to transform product design, bring agility to manufacturing and supply chains, and improve patient care.

To learn more about Stratasys, visit www.stratasys.com, the Stratasys blog, Twitter, LinkedIn, or Facebook.