The All-In Implant Concept

A simplified, time-saving approach to immediate placement that facilitates immediate or delayed loading as needed

Lon McRae, DMD | Marius Van Tonder, RDT | Gregori M. Kurtzman, DDS

Today, the majority of implants are placed using a 3-stage delayed approach.1 However, this can take 8 months to 1 year from extraction to the seating of the final restoration. The "All-In" implant placement concept allows practitioners to plan, virtually design, and fabricate everything needed to extract a tooth, place an immediate implant, and potentially place a final abutment with a custom temporary crown during a single appointment. Immediate loading can be performed when adequate insertion torque is achieved, and according to the literature, immediately placed implants have demonstrated a 97% success rate.2 If there is insufficient stability at implant placement to permit immediate loading, as a backup, the All-In concept provides a custom healing abutment to develop an emergence profile during implant integration until loading can be initiated, thus the name, All-In. Digital preplanning with the ability to virtually extract a tooth provides the practitioner with the exact emergence profile from the implant platform through to the restoration. Furthermore, virtual planning can help to facilitate partial extraction therapy (PET) to preserve the interdental papillae and support the soft tissue with little to no loss of bone.3,4

Immediate implant placement at single tooth extraction sites presents challenges related to the relationship between the tooth to be extracted and the adjacent anatomy. Due to the limitations of traditional radiography, cone-beam computed tomography (CBCT) is used to provide a 3D view of the area. Cross-sectional views through the ridge and its associated tooth aid in digitally planning the most ideal implant angulation and depth that can be accommodated by the site. In addition, virtual implant planning uses the information from the CBCT scan to enable the design of a 3D printed surgical guide, simplifying chairside treatment for the practitioner. Guided surgery requires a CBCT scan, virtual implant planning software, and the fabrication of a surgical guide to place the implant intraorally in the planned anatomical position. When compared with freehand surgery, guided surgery results in improved precision and accuracy in the placement of dental implants and has been associated with reduced failure rates.5-7

The All-In Workflow

Virtual implant planning can be performed in-office or submitted to an outside company to have a technician complete it. Utilizing an outside service saves time for the practitioner, and because the virtual plan is returned to the office for approval before the surgical guide is fabricated, the practitioner has final approval. Once the implant has been virtually positioned and the plan is approved, the surgical guide is virtually designed, 3D printed, and returned to the office in preparation for implant placement. For the All-In concept, all of the prosthetic components (custom healing abutment, custom final abutment, provisional restoration, etc) are prefabricated prior to the surgical appointment utilizing CAD/CAM milling and 3D printing and returned to the office along with the surgical guide. Performing the osteotomy and placing the implant with a surgical guide decreases the appointment time, and having all of the components needed to proceed, regardless of the implant's initial stability, further simplifies the clinical visit.

If adequate primary stability for immediate loading is achieved (ie, an insertion torque of at least 45 Ncm or an implant stability quotient [ISQ] value of 70), the custom final abutment can be inserted and the provisional crown placed with temporary cement in a matter of minutes, saving even more time when compared with the chairside fabrication and delivery of a screw-retained provisional restoration. This offers esthetic benefits because it eliminates the need for a provisional partial denture. Furthermore, immediate replacement of the lost tooth helps the patient maintain confidence, decreases the total number of visits for the patient, and reduces overhead for the dentist.

Should the insertion torque be deemed insufficient to immediately load the implant, the supplied custom healing abutment is placed to develop the desired soft-tissue emergence profile during the healing phase. After the implant has fully integrated, it is very easy to complete the All-In protocol because the custom healing abutment and custom final abutment are fabricated with the same emergence profile. The healing abutment is simply removed, the previously fabricated All-In custom final abutment is seated, and the final crown is placed. Beyond the time savings, with only one removal and reseating of the final abutment, the contact of the Sharpey's fibers is stronger and longer lasting.

When immediate placement is performed using a freehand technique, the extraction socket may deflect the osteotomy drill from its planned position, resulting in a less-than-ideal implant position. Utilization of a surgical guide prevents that from occurring, facilitating an ideal position and angulation of the osteotomy and subsequent implant insertion regardless of the nature of the extraction socket. Following placement of the implant, any surrounding areas of the extraction socket that remain open can be filled in with an appropriate osseous graft material prior to immediate provisionalization or insertion of the healing abutment.

Case Report

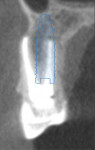

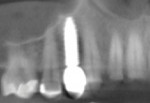

A 49-year-old female patient presented with pain associated with her maxillary right first premolar (tooth No. 5). In addition, she stated that she was unhappy with the existing restorations on her maxillary anterior teeth. A periapical radiograph was acquired to evaluate the tooth (Figure 1). It was revealed that tooth No. 5 had undergone prior endodontic treatment, and a periapical abscess was noted. During the clinical examination, the patient reported pain from palpation of the buccal aspect of the ridge and percussion, and marginal decay was noted on the anterior crowns. A CBCT scan was acquired to further evaluate tooth No. 5 (Figure 2). The cross-sectional view of the tooth revealed a dehiscence of the buccal root.

The clinical findings were discussed with the patient, and she was informed that tooth No. 5 had a poor prognosis due to the minimal tooth structure remaining, which resulted from overinstrumentation when the prior endodontic treatment was performed. The treatment recommended included extraction of tooth No. 5, PET to preserve the buccal aspect of the ridge, and immediate implant placement. Per the All-In concept, should adequate insertion torque be achieved, the implant would be immediately loaded with a custom abutment and a provisional crown, and if the implant's initial stability was inadequate, a custom healing abutment would be placed to shape the soft tissue during the osseointegration phase. The treatment plan would also involve replacement of the current anterior crowns but not until the implant was fully integrated and ready for the final restoration. The patient accepted the proposed treatment plan, and the CBCT scan was sent to the laboratory for implant planning and surgical guide fabrication.

Planning Phase

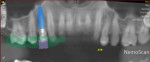

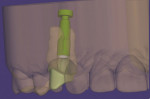

Once the technician imported the CBCT scan data into the implant planning software (NemoScan, Biotech Dental), a virtual implant was placed into the site of tooth No. 5 to fit the anatomy present. The current tooth was used to aid in guiding the positioning of the implant in 3D (Figure 3 through Figure 5). The virtual placement would take into consideration the tooth's dehisced buccal root, which would be maintained using PET. The software allowed examination of the planned implant position in relation to the current tooth's position to keep the implant within the clinical anatomy present (Figure 6). In order to best accommodate the site, a 4.2 mm ˟ 14 mm implant (Kontact™, Biotech Dental) was selected. A surgical guide was then designed in the software to guide implant placement into the virtually planned position (Figure 7 and Figure 8). The surgical guide would be partial arch and tooth supported both mesial and distal to the implant site (Figure 9). A virtual model of the maxillary arch was created in the software with the current tooth and its crown present, then the coronal aspect of the tooth was removed from the virtual model, and the virtual implant position was merged with the virtual model, placing it in the center of the ridge (Figure 10). To complete the surgical guide design process, the virtual surgical guide was merged with the virtual model (Figure 11). Both the model and the guide were then 3D printed (Form 3B+, Formlabs), and a metal guide sleeve was luted into the printed surgical guide to finish it (Figure 12).

After the virtual extraction and implant planning was performed in the implant planning software, the STL files needed for the CAD software (DentalCAD, exocad) were generated. Those STL files were then imported into the CAD software, and a custom healing abutment (Figure 13 and Figure 14), a custom zirconia final abutment (Figure 15), and a provisional resin crown (Figure 16 and Figure 17) were designed. The abutments and the provisional crown were milled with a 5-axis milling machine (CORiTEC® 650i, imes-icore GmbH). The provisional crown design would make the restoration screw retained once the crown was luted to the final abutment. This would allow the provisional crown and abutment to be retrieved after cementation to remove any residual cement that could affect healing and then reinserted in the same orientation with the implant and adjacent teeth. Alternatively, if sufficient insertion torque for immediate loading could not be achieved at implant placement, the design of the custom healing abutment would facilitate soft-tissue guidance during the healing period to develop a natural emergence profile. With the planning and fabrication complete, the custom healing abutment, custom zirconia final abutment, and provisional crown were sent to the doctor along with the model, surgical guide, and implant (Figure 18).

Clinical Phase

The patient presented for the surgical appointment, and a consent form was reviewed and signed. Local anesthesia was achieved with a buccal injection of one carpule of 3% mepivacaine and one carpule of 4% articaine (Septocaine®, Septodont). Using forceps, the existing crown was detached from the root structure, leaving the roots in the socket (Figure 19). The roots were then sectioned from the mesial aspect to the distal aspect, and the palatal root was extracted atraumatically with elevators. To complete PET, a carbide bur was utilized to contour the buccal root, leaving a shell on the buccal wall of the ridge, and remove any residual endodontic obturation material (Figure 20). The surgical guide was then seated intraorally to verify its fit and stability on the adjacent teeth (Figure 21).

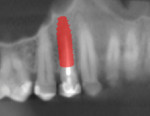

After the initial osteotomy was made with the pilot drill through the surgical guide, the guide was removed from the mouth, the pilot drill was inserted into the osteotomy, and a periapical radiograph was acquired to verify accuracy of the virtual planned position relative to the anatomy (Figure 22). The guide was then reseated intraorally, and the osteotomy was completed using sequential drills. Once the osteotomy was complete, the 4.2 mm ˟ 14 mm implant was inserted through the guide (Figure 23). Final insertion to depth was achieved with a calibrated torque wrench, which resulted in an insertion torque of 70 Ncm and an ISQ value of 72. Again, a radiograph was obtained to verify accuracy of the virtual planned position relative to the anatomy (Figure 24).

The carrier was detached from the implant, and the surgical guide was removed from the mouth. Upon removal of the guide, a gap could be noted between the implant and palatal wall of the socket and between the implant and the remaining buccal portion of the root following PET (Figure 25). The gaps were filled with an allograft material (OSSIF-i sem™ Mineralized Cancellous Bone, Surgical Esthetics) (Figure 26).

Because sufficient insertion torque was achieved, immediate loading could be performed. The custom zirconia abutment was inserted so that its margins were properly positioned in relation to the soft tissue, and the screw was tightened with a torque wrench (Figure 27 and Figure 28). The supplied provisional crown was then tried in and cemented with temporary cement (Temp-Bond™, Kerr Corporation). Following cementation, the fixation screw was loosened, the abutment and provisional crown were removed from the mouth, and any residual cement was cleaned from the crown-abutment margin. The crown-abutment complex was then reinserted intraorally, and the screw was tightened to the manufacturer's recommended torque of 20 Ncm. To complete the provisional restoration, a piece of PTFE tape was placed into the screw access hole, which was then filled with a flowable composite (Clip Flow, VOCO America) to seal it (Figure 29). The occlusion was checked to verify that the provisional crown was completely out of contact during all movements.

A postoperative CBCT scan was taken to document the implant's position in the mesial-distal plane and buccal-palatal plane in relation to the anatomy. The images were then compared with the planned positions in the initial CBCT scan. In the periapical view, the actual implant position matched the virtual planned position and was properly located relative to the adjacent teeth and the maxillary sinus floor (Figure 30 and Figure 31). A match of the actual and planned positions was also noted in the cross-sectional view, including adequate space between the buccal side of the implant and the exterior buccal wall of the ridge (Figure 32 and Figure 33).

The patient was provided with postoperative instructions, which included not chewing on the right side to avoid any loading forces that could interfere with osseointegration. She was then dismissed and scheduled for a follow-up appointment after 7 days. The implant would be allowed to osseointegrate for 3 months before final restoration would be initiated. At that time, the existing crowns on teeth Nos. 6 through 11 would also be replaced to eliminate the marginal decay and improve the esthetics per the patient's request.

Conclusion

The All-In concept uses virtual implant planning and a guided surgical protocol in combination with the prefabrication of all potentially needed prosthetic components to facilitate a more simplified surgical process. When immediate implant placement is performed, the surgical guide prevents the osteotomy drill from "jumping" in the extraction socket and achieves placement as was virtually planned. Implants with deep threads are well suited for the lower density bone of the maxilla and in immediate extraction sites to aid in achieving good initial stability and sufficient insertion torque to permit immediate loading. Fabrication of all of the prosthetic components prior to the surgical appointment facilitates both immediate loading and delayed loading approaches, depending on the needs of the case, while decreasing chairside time and the number of appointments needed as well as overhead.

About the Authors

Lon McRae, DMD

Fellow

International Academy of Dental Implantology

Private Practice

Meridian, Idaho

Marius Van Tonder, RDT

Director of Clinical and Technical Affairs

Biotech Dental USA

Gregori M. Kurtzman, DDS

Master

Academy of General Dentistry

Diplomate

International Congress of Oral Implantologists

Private Practice

Silver Spring, Maryland

References

1. Kan JY, Rungcharassaeng K, Lin GH, et al. Incidence of straight-channel screw-retained single crown following immediate implant placement and provisionalization in the esthetic zone: a CBCT study. Int J Oral Maxillofac Implants. 2021;36(4):793-798.

2. Garcia-Sanchez R, Dopico J, Kalemaj Z, et al. Comparison of clinical outcomes of immediate versus delayed placement of dental implants: a systematic review and meta-analysis. Clin Oral Implants Res. 2022;33(3):231-277.

3. Gluckman H, Salama M, Du Toit J. Partial extraction therapies (PET) Part 1: maintaining alveolar ridge contour at pontic and immediate implant sites. Int J Periodontics Restorative Dent. 2016;36(5):681-687.

4. Gluckman H, Salama M, Du Toit J. Partial extraction therapies (PET) Part 2: procedures and technical aspects. Int J Periodontics Restorative Dent. 2017;37(3):377-385.

5. Gargallo-Albiol J, Barootchi S, Marques-Guasch J, Wang H-L. Fully guided versus half-guided and freehand implant placement: systematic review and meta-analysis. Int J Oral Maxillofac Implants. 2020;35(6):1159-1169.

6. Abdelhay N, Prasad S, Prasad Gibson M. Failure rates associated with guided versus non-guided dental implant placement: a systematic review and meta-analysis. BDJ Open. 2021;7(1):31.

7. Fernández-Gil Á, Gil HS, Velasco MG, Moreno Vázquez JC. An in vitro model to evaluate the accuracy of guided implant placement based on the surgeon's experience. Int J Oral Maxillofac Implants. 2017;32(3):151-154.