Innovative Strategies for Cemented Implant Restorations

CAD/CAM technology offers laboratories digital workflows to help ensure clinical success

John Wilson

Implant dentistry and restorative treatment protocols are coming full circle as dentists and dental technicians gain greater clarity and understanding through experience and previous mistakes. Twenty-five years ago, screw-retained implant-supported restorations were extraordinarily common. However, as the number of implant fixtures being prescribed and placed by surgeons and general practitioners increased, the use of screw-retained implant-supported restorations gave way to the use of prefabricated stock solid abutments with cemented restorations. Often, this restorative treatment process was chosen for a number of perceived benefits. Costs for the surgeons and the restorative clinicians were significantly reduced by the use of prefabricated stock abutments, and the practitioner's comfort level was greater using this more traditional restorative protocol, especially for those who placed and restored single implant sites. In addition, poor surgical planning for screw-retained restorations sometimes led to screw access holes that emerged in critical esthetic areas, like the facial aspect of the tooth, which necessitated a cemented restoration to cover the access hole.

Costs for parts inventory also influenced the decision by specialists to use stock abutments. It was very common for a general practitioner to refer their patients to an oral surgeon, only to have the surgeon choose the restorative treatment process. The stock solid abutment was often the surgeon's choice, as it required a smaller inventory of parts and was not tied to the constraints of a patient-specific restorative process. It also allowed for an inexperienced referring client to proceed with a simple impression and what was considered a simple delivery of a cemented crown, since it closely mirrored a traditional fixed treatment protocol.

However, there were significant drawbacks to this technique if not done properly. Upon cementing the crown, the restorative dentist needed to adhere to a very specific cementing protocol and ensure all cement was properly cleaned. Studies have shown that cement left at the implant site could lead to peri-implantitis and ultimately cause the implant to fail prematurely. Peri-implantitis, while not exclusive to cement-retained restorations, became a more common occurrence as more dental implants were placed and restored. One of the largest contributing factors could be traced to improper cementation protocols. Some of the most basic protocols to limit cement clean-up were not being implemented. Furthermore, it was increasingly difficult to retrieve a restoration if the abutment screw backed off the abutment of a cemented crown.

Today the use of CAD/CAM technology allows numerous ways for a dental laboratory to support its clients using successful and proven digital workflows leading to cementation success. Patient-specific custom abutments, designed and in some cases fabricated in the dental laboratory, truly support the overall success of the implant-supported restorative process. Custom abutments take into account the patient's surrounding tissue, and the slight concave contours of the intaglio side of the abutment actually promote healthy blood flow in the gingival area, leading to the tissue healing toward the abutment naturally. Furthermore, the proper emergence of the restoration from the custom abutment functions much the same as a natural tooth and deflects food away from the gingiva, increasing the health and hygiene of the implant site. Although screw-retained restorations are among the largest number of prescribed implant-supported restorations today, there are still many times a cemented case is more advantageous. The author will present some strategies that laboratory technicians can implement to aid their clients in successful cementations when designing and delivering custom implant abutments.

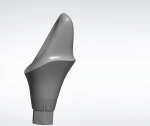

Custom Abutment Design

Proper emergence and margin depth have always been important. However, understanding the client's challenges with cementation and post-cementation protocols will help the laboratory design its next patient-specific abutment more appropriately (Figure 1). While tissue bio-type can be challenging with titanium abutments, the best thing to do is to place the margin heights close to equigingival with the sulcus-starting at the mesial and moving around the lingual to the distal. This will allow for a "vent" and easier cement clean-up, since any excess cement will vent out and be easily seen by the clinician.

Additionally, when designing abutments, pay close attention to how the crown emerges from the abutments, a detail that is equally important. Proper understanding of machining constraints on margin preparation design will help to make the transition from abutment to crown more uniform. A thick margin line offset is not conducive to an optimum transition interface, and instead there should be a seamless transition between the abutment and the cemented crown.

Radiographic Imaging

Requesting radiographs for proper emergence design has traditionally not been the norm. However, with the advent of bone-level fixtures, many being placed subcrestal, a keen understanding of the potential challenges that could be confronted may only be seen with the use of radiographs, which certainly merits the use of this new workflow for the laboratory. In addition, there are other benefits to radiographing the site to ensure that the impression coping is seated in the implant fixture properly.

• Radiographs allow for simple verification of a properly seated impression coping in the fixture.

• On multiple-unit cases, where a client may use different heights of impression copings, radiographs allow for clear communication and confirmation of proper placement based on size and location.

• Radiographs can illustrate emergence difficulties based on crestal bone ledges that would not be known by the laboratory without this additional information.

Once the properly designed abutment and crown are ready to deliver, a laboratory can aid its clients by providing two additional products and solutions along with the case: a duplicate master die and an endo jig.

The use of a duplicate master die—a milled or printed PMMA replica of the custom abutment—will allow clients to easily dispense and flow excess cement out of the crown prior to seating intraorally. Utilizing the duplicate die to coat the inside of the crown with just the right amount of cement will minimize the amount of cement clean-up. This can be critical and help even further in cases that absolutely must be designed and fabricated deeper in the sulcus with subgingival margins on the abutment.

A retrieval jig, also known as an endo jig, has become a useful clinical assistance product in implant dentistry for retrieving abutments when the screw backs out of the implant fixture. With the digital workflows used today, it is exceptionally easy to manufacture what looks like an abutment seating jig but is actually a tool used when a loose screw must be accessed through a cemented crown. This jig will seat over the cemented crown, and a perfectly designed channel will follow the long axis of the fixture and provide a clean path to the screw (Figure 2 through Figure 4). Over the years, there have been a tremendous number of restorations that suffered from abutment screws coming loose. Many times, this has necessitated that the clinician perform a "hunt and find" protocol, essentially destroying the crown to gain access to the screw. Today, it's advantageous to have clients order this little jig when prescribing cemented restorations, as it is some of the cheapest insurance they can have. Using this jig can help ensure that crowns may not need to be replaced if a screw comes loose.

In conclusion, with the rise of proper presurgical planning, fewer cemented restorations are being placed today. As the industry has not yet fully implemented the screw-retained implant treatment protocol as the standard of care, it is wise to have options that allow laboratories to be a support resource for their clients.

About the Author

John Wilson is a 30-year veteran to the trade and owner/operator of Sunrise Dental Laboratory, located in Yucaipa, California. His lab specializes in full mouth reconstructions and strives to embody the “team approach to dentistry.”